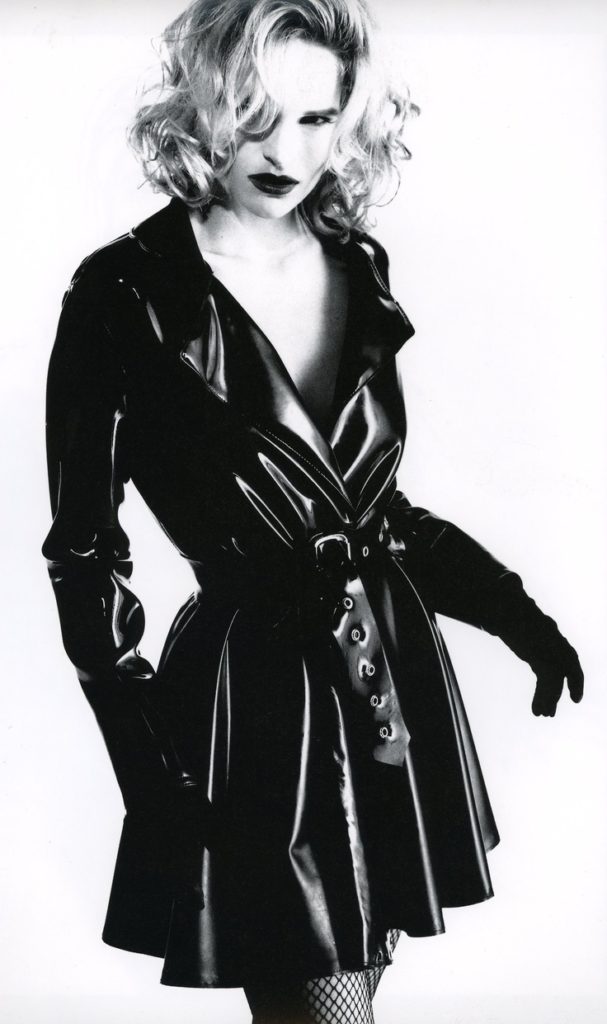

Faux leather versus leather hides

Do you struggle to understand the difference between leather hides and faux leather fabric? Are you wondering which one to choose for your upcoming project? We’ll review the differences between leather hides and the many various types of faux leather, illustrating when to use each and why.

Leather Hides

Leather hides come from animals and the type of animal and treatment that the hide goes through dictates the qualities of the material. Some of the more popular animals that are processed for hides include cow, goat, lamb, kangaroo, and pigs.

Woman wearing brown dress

There are also what are referred to as exotic hides like snakeskin, alligator hides, and alpaca to name a few. Exotic hides are those that are rarer and generally cost more.

The skin is removed from the animal post-mortem and then it goes through several different physical and chemical processes before being offered for sale. We won’t cover all those different processes in this post, but you should be aware that it is labor intensive which is why leather hides are significantly more expensive than faux leather fabrics.

Leather hides are priced by the square foot and you can expect anywhere from $4.50 to $35 per square foot depending on the hide and specific processing that it has gone through. As a comparison to faux leather fabric, a 56 inch wide fabric that is one yard in length would be about 13.5 sq ft and you would pay about $10 for faux leather whereas, 13.5 sq ft of average cost leather hide would be about $100 (about 10 times the cost).

So why would you buy a leather hide instead of faux leather fabric? Let’s continue on by reviewing how faux leather fabric is made and then we’ll compare which type of material is best for specific applications and projects.

Faux Leather

Faux leather goes by many names: veggie leather, imitation leather, pleather, fake leather, vinyl embossed fabric, etc. The primary different between faux leather and a leather hide is that faux leather is manufactured by applying a chemical coating to a woven or knitted backing.

The price does not vary as widely as that of leather hides, and you can typically find imitation leather fabric for between $6.00 and $16.00 per yard. The price is largely depending on the following factors:

- Fabric backing color: White, tan, and black are common colors for the backing material. If the backing color is customized to any other color it adds cost. White or tan material must be dyed to match the top coat color, and the dyes add cost and labor to the process. MJTrends matches the backing color to the topside coated color so that when it is sewn a different color does not show through holes made by the sewing machine needle, and also if the back of the material is exposed like on a collar or a loose flowing dress, the color matches.

- The coating material: There are different types of materials that can be used for the coating material. Without going into too much detail, they fall largely into two groups: polyvinylchloride (PVC), and Polyurethane (P/U). PVC tends to be stiffer, is less environmentally friendly, and is cheaper. P/U tends to have a softer feel to the touch, more flexibility, and is more costly.

- Embossment: During the coating process, the material can be stamped to give it an embossed pattern like that of a crocodile skin, alligator, cobra, python, etc. Embossing the material adds another level of labor to the process and increases costs.

- Backing material: These can include woven, knit, flannel, 2-way stretch, 4-way stretch, etc. The fibers used can vary among 100% cotton, 100% polyester, cotton/polyester blends, cotton/spandex blends, wool, nylon, rayon, and more. The higher quality the backing material, the greater the cost of the final product.

Leather Hides versus Manufactured Faux Leather Fabric

So which of these options should you choose for your project? Let’s cover the advantage and disadvantages of each.

Leather Hide Advantages: Hides carry a certain level of Cachet or prestige. If you are making finished goods for the luxury market or for a narrow clientele who are leather purists such as in certain outdoor markets, then leather hides are the clear winner. Humans have worn leather for centuries and it has a distinct look and feel that appeals to specific purchasers.

Kangaroo skin has a thickness and durability that is unparalleled in manufactured leather. These skins are used for motorcycle jackets and clothing where the ability to withstand sliding across pavement at 60 MPH might be the difference between life and death (or at least severe disfigurement).

Leather hides also beat out imitation leather fabric in regards to historical accuracy. If you are making a corset or wristband for a historical reenactment, renaissance faire, or other production based on outfits from hundreds of years ago then it may be important to maintain veracity with the targeted period.

Patina – this is what happens to leather as it ages. It is the manifestation of the natural ageing process that results from exposure to sun, water, and regular wear and tear. Patina is the lore that forms in a favorite bag or article of clothing that tells the story of your personal history with the item.

High quality leather will develop a patina that increases the value of the item over time. Manufactured veggie leathers will never develop a patina, regardless of the quality of processes involved.

Lastly, similar to Patina, no two leather hides will be exactly alike. This gives personality and uniqueness to the items you are crafting. If your buyers care about having something novel and distinct, using leather is one more method of providing them with exclusivity and novelty.

Imitation leather Advantages: The easiest advantage to see when comparing leather hides to imitation leather is cost. If you are not selling to a luxury market or a customer that has a strong preference for real leather, then faux leather can help keep your costs low, thereby resulting in greater sales or profit margins.

Durability: While kangaroo leather is an excellent example of the durability of particular leather hides, most people won’t be sourcing it for fashions or other uses. The majority of leather hides that are used are lambskin, goatskin, and cow skin, and faux leather fabrics, although thinner, can be significantly harder.

The hardness of a material is known as it’s durometer scale, and a the harder it is the more resistance it will be to scratching and staining. While leather may develop a patina over time, your vinyl fabric will more likely remain in pristine condition despite being dragged through your car, bumped against the door handle, etc.

Additionally, softer leather hides may become stained by that overturned glass of wine, whereas manufactured vinyl fabric is largely resistant to that type of staining.

Consistent appearance: Previously we stated that no two leather hides are alike, but what if you want or need consistency for your products? You can guarantee the same size, thickness, patterns, color tone, etc. when working with faux leather.

Easier to work with: Even the thinnest and lightest-weight leather hides are going to be thicker than most veggie leather fabrics and will require a sewing machine and heavier-duty needles that can consistently penetrate the material.

Faux leather fabric is easier to sew than a leather hide. Regardless, MJTrends offers several sewing notions to assist you with either. For vinyl fabrics we recommend a teflon coated presser foot or roller foot and “sharp” style sewing needles. For leather hides and our thicker embossed coated vinyl we recommend using a leather needle and we also have awls available for penetrating leather to create holes.

If reading the above hasn’t helped you sort out which material to use for your project, we have a questionnaire below that will help:

- Is it a luxury market that prefers real leather?

- Does my customer have a reason to prefer real leather?

- Is cost important? Will I sell more with a lower price point?

- Is consistency important or is uniqueness of the material important?

- Do I have the tools and knowledge to work with leather hides?

- Is patina important or is better to have greater durability?

Email App

Email App

No Comments